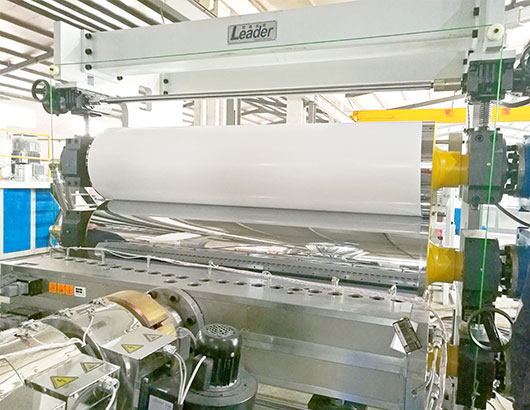

PC Multiwall Hollow Profile Sheet Extrusion Line

Zvimiro zvemitsara

1) Kumhanya kwepamusoro, kuchengetedza simba, screw yakagadzikana, uye inogona kuwedzera huwandu neinodarika 25%, zvichienzaniswa nemimwe michina yakafanana.Iyo screw yakasarudzika dhizaini inogona kuve yakanakisa plasticizing mhedzisiro uye yakagadzikana extrusion.

2) Sikirini inoshandura + inonyungudutsa giya pombi: hydraulic inokurumidza shanduko yezviratidziro inogona kunyatso kumisa kusvibiswa kweiyo mbishi uye kuvimbisa mapepa emhando.Iyo pombi inonyunguduka inogona kuita kuti iyo yakasvibirira yemidziyo igadzikane kuvimbisa yakagadzikana extrusion.

3) co-extruder dhizaini uye feed-block yeUV yekupotera pamativi ese

4) Iyo T die mold inogadzirwa neyemhando yepamusoro alloy mold simbi, yakanyatso gadzirwa kuyerera nzira dzePC hollow profiles, inotakurika inotakurika mudziyo inogona kuvimbisa kudzvanywa kweiyo mbishi kuyerera mukati meT kufa yunifomu kuti ive nechokwadi chekuti mapepa akakora yunifomu.T die mold inogona kugadzirwa kune yakavharwa mhando isina mipendero yekucheka zvinoenderana nezvinodiwa nevatengi.

5) Yakanyatsogadzirirwa kugadzirisa mudziyo nekutonga kwega kwega unit;Iyo vacuum system inoumbwa nezvikamu zviviri.Imwe neimwe subsystem yakashongedzerwa neakawanda matatu-poinzi yakagadziriswa cycle vacuum mapoka.Imwe neimwe yakagadziriswa kutenderera inotakura vacuum gadziriso system uye vacuum kuratidza sisitimu kuti iite vacuum degree yeplate pamusoro yunifomu uye yakagadzikana.

6) Kune maviri maseti emichina yekudhonza.Iyo yekutanga seti ine gumi nemaviri mapikicha ekupfeka-resistance rubber rollers uye yakakwirira simba, iyo inogona panguva imwe chete uye yakafanana kudhonza mapepa kubva pavacuum calibrating tafura.Yechipiri yekubvisa muchina inobatsira kubvisa kushushikana kwepepa.

7) Transverse cutter: Yakashongedzerwa neiyo chaiyo yakamisikidzwa-kureba yekucheka, yakakosha alloy kupfeka-inodzivirira mablades ane yekudziya mudziyo kuti ive nechokwadi cheplate yemhando yakachekwa.

8) Yese mutsetse inotora zvizere otomatiki Siemens PLC yekubata sikirini kudzora;iyo yemagetsi yekudzora midziyo inonyatso optimize yese mutsara mashandiro uye inowana yakakwirira mhando uye yakakwira kubuda.

Mashandisirwo makuru ePC hollow sheets

PC hollow sheet ine yakanakisa insulation uye murazvo kuramba kuita, huremu huremu, kusimba kwesimba, kureba kwenguva refu kutapurirana, kunoshandiswa zvakanyanya mukuvaka zvivakwa, kuvharira kwezvivakwa zvikuru, dzimba dzekurima dzekurima, dziva rekushambira, denga rekugara uye maindasitiri uye kupenya, mapaneru emadziro. zvemukati dhizaini zvikumbiro;solar applications, advertising signage etc.

| Model | LMSB110/35 | LMSB120/45 | LMSB130/45 |

| Suitable material | PC, UV+PC | PC, UV+PC | PC, UV+PC |

| Product width | 600-900-1220mm | 2100mm | 2100mm |

| Product ukobvu | 4-30mm | ||

| SHeet chimiro | A/B/A 3 akaturikidzana co-extrusion, ine UVcoatedkumativi ose | ||

| Mdemo kugona | 200-300kg/h | 300-400kg/h | 400-500kg/h |